How vinyl records are made

INTRO

Personally, my goals for being on HIVE are to value my identity and build my wealth.

Here, wealth is built with rewards from publications and investments in some of the products that HIVE offers, namely second-layer tokens, games, etc.

The enhancement of my identity is achieved through knowledge. Either by consuming interesting publications that are made here or by seeking out that knowledge. This publication is a case in point!

It was no longer news to me that the vinyl industry is making a strong comeback. What I didn't know was how vinyl records were made.

After some research, I learned that there are two vinyl record factories in Portugal. My relentless desire to learn led me to contact the factory that was geographically closest to me to arrange a visit. Located in Maceira, Leiria, Grama Pressing welcomed me last Wednesday.

It started off well, as the owner of the company, Hugo Ferreira, is an acquaintance of mine. We hadn't seen each other for about 20 years, but we used to spend a lot of time together at the Coimbra Academic Association building. Hugo went to study law in Coimbra and attended Rádio Universidade de Coimbra, while I attended the Photography Study Center next door.

The first two hours of this meeting were spent reminiscing about the past, when we used to enjoy creating philosophical phrases just to laugh at them afterwards. We wanted to keep the tradition alive and created a new one: “Coincidences are chance encounters prepared by the Gods (whatever they may be).”

Well, let's get down to business.

The factory: Grama Pressing

Founded in late 2021, it began producing vinyl records in the city of Maia, in northern Portugal. However, it moved to Maceira (Leiria), where Hugo's parents have mold factories. This change of facilities brought advantages in terms of maintenance, logistics, and energy resources.

Around 10 people work in the different areas of production. They export to 40 countries, mainly in Europe, and print records of different musical genres. From rap, popular music, jazz, pop-rock, experimental music, and Romanian hip-hop.

However, they still depend on third parties for two stages of production. Grama Pressing plans to invest € 750,000 by the end of 2026 to become completely independent in production.

Hugo Ferreira kindly took the time to show us the different stages of vinyl record production.

STEP 1 – Mastering

Mastering is the final stage of recording (in the studio) for an album, but the first stage in the vinyl production process.

Customers deliver their pre-recorded songs in .waiv or .aiff format to be meticulously worked on by an engineer, who adjusts the sound for analog format.

To ensure that the sound does not distort during pressing, the engineer balances the sound and dynamics. A master is then created for customer approval.

Only with this approval can the next step be taken.

STEP 2 – Lacquer Cutting or Lacquer Coating

This stage transfers the audio master to the initial mold that will be used to create the discs. This mold is an aluminum disc covered with black lacquer.

The cutting lathe is a machine that receives the audio signal and uses a needle to engrave grooves into the lacquer disc. The lacquer, or matrix, is the main component of the entire process.

Here, the high and very high frequencies are tuned, which can distort the music. The low frequencies are also adjusted, as they can cause the needle to skip during playback. Other technical interventions are made to improve sound quality.

STEP 3 – Electroplating or Galvanoplasty

This is one of the stages that Grama Pressing outsources to a third party. In this case, a German company. It is a chemical process where the “stamps” that will press the vinyl are created.

This process has three phases. Since I did not witness this stage, with a brief explanation from Hugo, I turned to Gemini chat to be more precise. In this chemical process, the following happens:

Nickel Mold (Father): The lacquer is coated with nickel through an electrolytic process. When separated from the lacquer, this layer of nickel, which is a negative copy, becomes the main mold (father).

Matrix (Mother): The master mold is again subjected to electroplating to create a positive copy, called the matrix (mother).

Stampers: Finally, the matrix is used to generate the final negative copies, called stampers, which will be used in vinyl presses.

A preview test is carried out with the stampers and sent to the customer for approval, without first undergoing quality control.

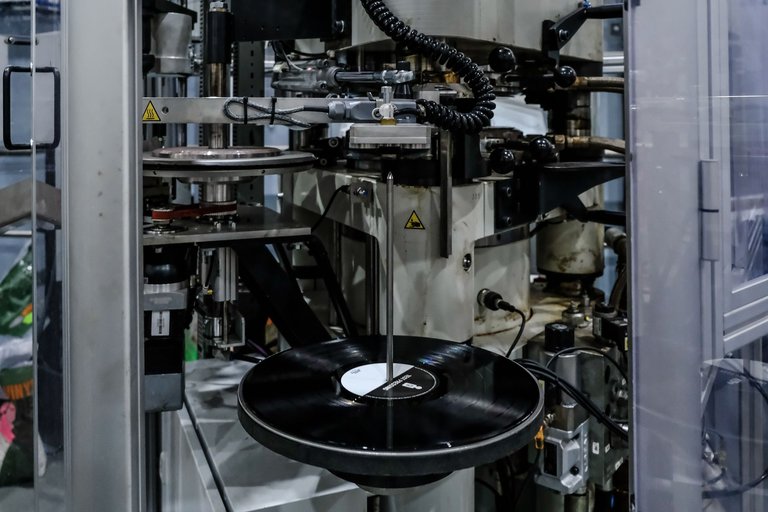

STEP 4 – Pressing

[This is where the magic happens]

This is the automated machine that performs the pressing. Three in one. First, small PVC pellets are heated and transformed into a vinyl “wafer.”

These are the small lvc balls that will shape the disc. They come in various colors, depending on the order.

This is where the PVC pellets take shape. They mold a mass of PVC.

This PVC compound called “wafer” comes out very hot.

Then this “wafer,” a piece of vinyl with no grooves yet, is placed between the two stampers — for Side A and Side B of the record.

In a third stage, the label is pressed and fused into the vinyl.

The labels are left in an oven for a day to remove moisture so that there are no imperfections.

After pressing, the days are left to rest under weight so that they do not deform.

STEP 5 – Artwork: design, covers and booklets

Some musicians and bands provide all the artwork to be included on the album in advance. However, Grama Pressing has a graphic design department that can do this work. All of this is handled initially, at stage zero when the order is placed, so that the covers and booklets can be printed using letterpress. This letterpress printing is done externally.

STEP 6 – Packaging and shipping to the customer

This is the final part of the process. There is a rigorous review, disc by disc, and organization of production for the different clients.

Sometimes discs need to be numbered, especially in collector's editions.

Almost ready to pack. First, the discs are wrapped in cellophane.

Packaging is an important part of safe shipping.

Everything is ready for the carrier to pick up and deliver to customers.

Here it is, in our home, in our collection. I hope you now have a clearer understanding of the various steps involved in the production of this company's vinyl records.

After the initiatives: @CryptoCompany [Banner for Boost], Lovesniped and Hive onboarding app Check in With, it’s time to highlight the friendly @dustbunny.

👍 Are you one of those people, like me, who likes to give a small reward when interacting with other users through comments?

🚨 Then you should know that rewards below $0.020 are never actually paid out. Your gesture has no effect. It just consumes your RC and leaves dust. That's where DustBunny comes in.🥕🐇

The cute @dustbunny stops munching on carrots and goes to look at the votes that are in this condition, dusty, and rewards them with the difference so that payment is possible. It cleans up the dust, in other words. Sensational, isn't it?

The cleaning is free, but DustBunny needs carrots to feed its voting power. That's where you can delegate a small portion of your HP to him to stock up on carrots. The HP is always yours. You can disconnect the delegation at any time. Here is all the information.

Wow! This is a fascinating and well documented informative post about your visit to Grama Pressing (Vinyl Pressing Plant).

Thank you for sharing with us the detailed process and more importantly I'm thrilled with how you started in the opening paragraph sharing the learning process with your broader goals on Hive.

My dad use to own a couple of these when we were growing up with amazing sounds but it is not really in vogue in this part of the world anymore. He has so many of those sounds which we classify as classics in this modern age.

Thanks for sharing @cryptoreforma.

I really appreciate your comment. Thank you very much.

It's my pleasure. Have a great time.

This is amazing!

I work with german RAND MUZIK pressing plant, and the process is same, but I really enojed watching all the great photos!

Thanks a lot 🤝

Nice great amazing

Thank you for sharing this @cryptoreforma - it's fascinating!

Thanks a lot, friends 🤝

Nice insight! I love that I can use digital music nowadays, but there are some downsides... With every medium. I remember transporting kilos of disks and heavy players/mixer as a young DJ. So it is a pain... Digital DJing offers soooo much benefits.

But:

Save the vinyl!

Just because modern cars are more awesome in some aspects, we don't should forget to care about a Ford Model T.

All (well) said.

Thanks a lot, friend 🤝

Wow! That's so cool they let you visit the factory and see the whole production process. It seems very high tech for a nostalgic item, I wonder how the production process differs from the old days

Thanks for showing us, it's very interesting

Thanks a lot, friend 🤝

It's fascinating to learn about this process, and you brought it to life with all the step-by-step details ✨ Seeing the stamps and the wafer was so interesting 💖 Your passion for learning and sharing knowledge really shines through in this 💕 This is so cool and amazing! 🙌

Thanks a lot, friend 🤝

Knowledge, learning, are part of our growth.

Most of my "For You" section on TikTok is with this process. I recently discovered it ,and it seems so satisfying to watch that the algorithm does its job to suggest more and more vids daily. It must be such a cool experience to see with your own eyes IRL!

True. The algorithm follows us, in this case for good reasons.

Thank you very much for the comment.

The pleasure was all mine! Thanks for sharing such awesome content on here!

Very good post and interesting production process. It must have been an exciting visit to the factory. I would love to see it live.

Thank you very much, friend 🤝

It was also very moving to see a friend I hadn't seen in over 20 years, the owner of the company.

Hello cryptoreforma!

It's nice to let you know that your article won 🥉 place.

Your post is among the best articles voted 7 days ago by the @hive-lu | King Lucoin Curator by deepresearch

You and your curator receive 0.0001 Lu (Lucoin) investment token and a 7.76% share of the reward from Daily Report 767. Additionally, you can also receive a unique LUBROWN token for taking 3rd place. All you need to do is reblog this report of the day with your winnings.

Buy Lu on the Hive-Engine exchange | World of Lu created by @szejq

STOPor to resume write a wordSTARTThank you very much for your report. I'm happy.

https://www.reddit.com/r/Factories/comments/1mzbv7d/how_vinyl_records_are_made/

This post has been shared on Reddit by @cryptoreforma through the HivePosh initiative.

Congratulations @cryptoreforma! You have completed the following achievement on the Hive blockchain And have been rewarded with New badge(s)

Your next target is to reach 3000 replies.

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPWow, on this digital era, you still producing the vinyl. I curious how the market is responding it ?

Good luck with your passion :)

I'm not the one producing it. See the text of the publication 😉

The vinyl market is indeed experiencing a renaissance.

Thank you very much.

oh yeah I mean your acquaintance

@cryptoreforma, I paid out 4.846 HIVE and 0.979 HBD to reward 11 comments in this discussion thread.

Wow amazing very interesting

Had to give this post as big of a vote as I could, amazing!

😀 Thanks a lot, friend 🤝

I'm glad you liked it.